Applications / KRAL / Marine / Hermetically Sealed Three Screw Pumps With Magnetic Coupling

Hermetically Sealed Three Screw Pumps With Magnetic Coupling

Hermetically Sealed Three Screw Pumps With Magnetic Coupling.

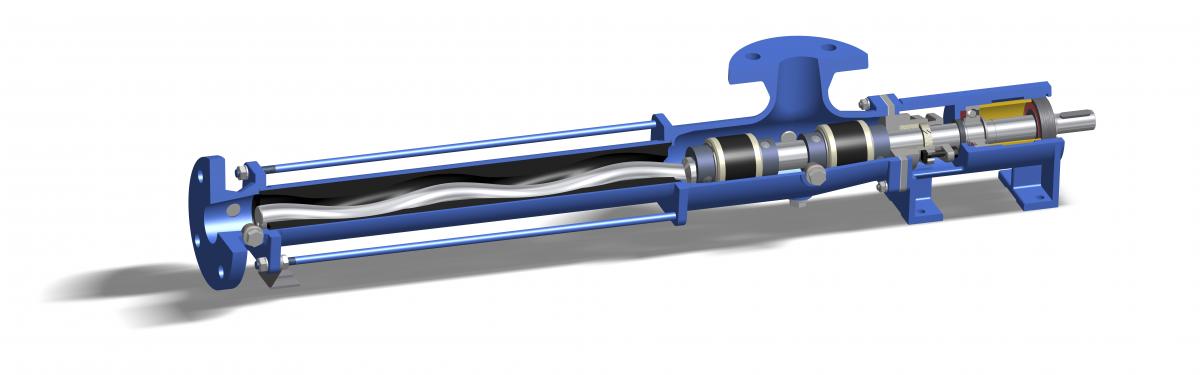

No more problems with mechanical seals.Experience for many years. KRAL has been making magnetically coupled three screw pumps for many years. We manufacture the components to our design standards. This means that the magnetic coupling perfectly matches the requirements of the KRAL three screw pump.

Mechanical seals reach their limitations at pre-heating temperatures of HFO 380 and 700. Refineries produce increasing amounts of lighter distillates out of a barrel of crude oil. This results in decreasing quality of the remaining residual oil. That is also the reason why HFO 380 and 700 came onto the market. These fuels must be pre-heated to 180 °C instead of to 150 °C, as is the case for HFO 380, in order to reach the low injection viscosity. Mechanical face seals can be used up to 180 °C, meaning they are at their limits. Magnetically coupled KRAL three screw pumps can be operated at up to 300 °C.

Fire on board is one of the biggest risks for crew and cargo. Fuel leaks and spray present an ignition source, which can quickly spread into a fire throughout the entire engine room. According to SOLAS, high pressure fuel lines must be double walled. This does not apply to booster module pumps, although mechanical seals present a risk of considerable leakage. In order to close this safety gap, KRAL has been highly recommending three screw pumps with magnetic coupling for years. The containment can of the magnetic coupling is an absolutely secure barrier. The risk of fire is greatly reduced. Another fire risk originates in the regulation of lowsulfur fuels. Operating in SECAs practically requires the use of distillates fuels. However, MDO has a flashpoint of 60 °C. A MDO leak at a mechanical seal is extremely dangerous given the hot surfaces in the engine room. The completely sealed magnetic coupling also avoids this fire risk.

Advantage:

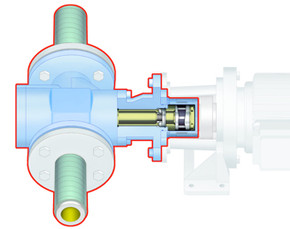

The containment of the magnetic coupling completely encloses the liquid between the pipe connections.

Disadvantage:

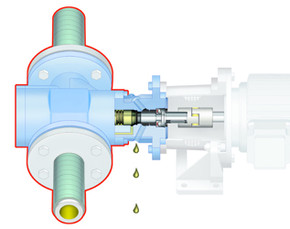

Interruption of the sealing contour by the necessary leakage of the mechanical seal.

Running the pump dry can damage the mechanical seal. Mechanical seals require forced lubrication. Purging and filling is required prior to the startup of a three screw pump. If this work is not carried out, the mechanical seal will run dry and can be destroyed. KRAL three screw pumps with magnetic coupling provide additional protection in the event of incorrect commissioning.

Solid materials in the fuel can lead to blocking and damaging the three screw pump. In many cases it is not worth to repair the three screw pump, and it must be replaced. The magnetic coupling can prevent damage to the three screw pump if screws block. The motor uncouples from the three screw pump. The cause can be corrected and the three screw pump restarted.

In order to keep the retrofit from previous KRAL three screw pumps with mechanical seal to KRAL three screw pumps with magnetic coupling simple, KRAL offers conversion kits that keep the foot and pipe connection dimensions unchanged. Two reasons cause some dimensions of the magentically coupled three screw pump to change: