Applications / KRAL / Marine / Solutions for Cylinder Lubricating Oil Measurement

Solutions for Cylinder Lubricating Oil Measurement

Solutions for Cylinder Lubricating Oil Measurement.

No more problems with mechanical seals.

KRAL cylinder lubricating oil measurement for 2-stroke engines.

Lubricating oil is significantly more expensive than fuel. It not only

lubricates the cylinders, it also protects them against corrosion and

sedimentation with the help of additives. The additives make lubricating oil

expensive. Operating costs rise when too much lubricating oil is injected.

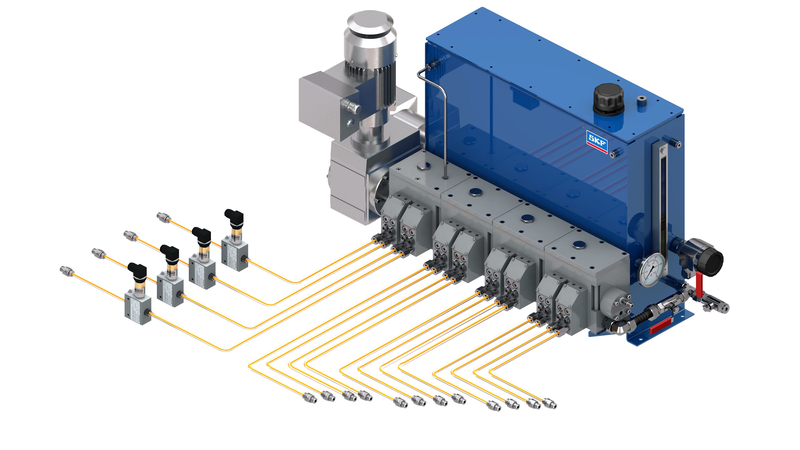

The spectrum for setting the lubricating oil quantity extends from

mechanically assisted injection systems to computercontrolled systems. The

injection quantity throughout the entire load area often doesn‘t agree with

the injection quantities programmed in the controlled system. Only measuring

offers information that ist not provided by any control system. The KRAL

cylinder lubricating oil measurement fills this gap and enables highly

precise measurement.

Avoid engine damage.

Too much lubricating oil damages pistons and cylinders. Lubricating oil

contains additives for protection against corrosion and sedimentation. Too

much lubrication can result in additive deposits between the piston rings.

Piston rings can break. That‘s expensive. With the KRAL lubricating oil

measurement, the operator receives correct measuring values. The injection

quantity can be set exactly with this information. That prevents engine

damage.

Take fuel quality into account.

The quantity of lube oil depends upon the sulfur content of the fuel. When

combusted, sulfur reacts to become sulfur dioxide, which, through sulfur

trioxide in combination with water, has a strongly corrosive effect and

attacks the cylinder liner. After each bunkering it must be tested whether

the sulfur content has changed in comparison to the previously used fuel. In

case that the fuel is different, the lubricating oil quantity must be

adjusted. Engine manufacturers provide operators with aids, for example,

setting tables. The KRAL lubricating oil measurement shows whether the

manufacturer specifications are actually being achieved.

The best possible measurement precision is extremely important.

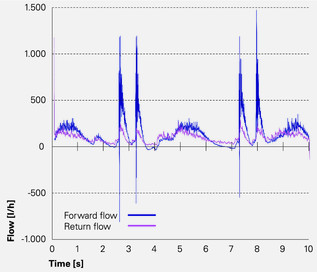

Due to the interaction of the actions of a number of injectors, the lubricating oil flow in the supply flow is not constant, but rather chaotic. This is a difficult measuring task that encompasses strong flow fluctuations and periodic backflows. With some injection systems, the lubricating oil also serves as servo oil for the operation of the injectors.

Due to the interaction of the actions of a number

of injectors, the lubricating oil flow in the supply flow is not

constant, but rather chaotic. This is a difficult measuring task

that encompasses strong flow fluctuations and periodic backflows.

With some injection systems, the lubricating oil also serves as

servo oil for the operation of the injectors.

The movement of the injection pistons cause pulsations and

considerable backflow quantities in the oil flow as a consequence

(see graphic). In addition, the cylinders of the engine are supplied

with varying lubricant quantities at different times. The oil flow

is anything but constant. Difficult in terms of measuring is that

the lubricating oil quantity to be measured is far less than the

total flow quantity dominated by the servo oil demand. Because a

considerable part of the lubricating oil is directed back from the

injector to a reserve tank, the consumption measurement is only

successful as a differential measurement of two measuring values in

the case of systems with a ring line.

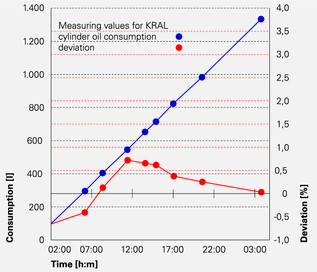

In addition to this, backflows must be recognized and subtracted for a current measurement value. The temperature in the oil tank can be significantly less than in the injectors close to the hot engine. This means that density differences of the cylinder oil at the two measuring points must also be taken into account. KRAL Volumeter are highly precise flowmeters (see graphic). They function equally in both flow directions. They are equipped with a sensor that recognizes the rotation direction of the screws and with a temperature sensor. They therefore take into account the special properties of the oil flow and deliver exact measurement results.Lubricating oil measurement over the course of a day. The measurement error in comparison to the level measurement converges toward zero.