Products / Kral / Screw Pumps / Screw Pump Magnetic Coupling K/L/C

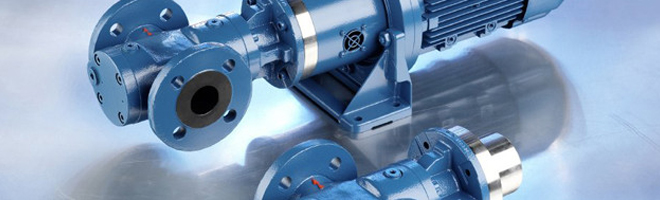

KRAL Three Screw Pumps with Magnetic Coupling.

No more mechanical seal problems.KRAL pumps are also available with magnetic

seals. Magnetic coupled pumps from KRAL are maintenance free,

hermetically sealed and can be used at temperatures of up to 300 °C.

Additionally, the lifespan of the ball bearings is considerably

extended.

Leakage-free and clean.

Critical fluids containing substances endangering the health or the

environment should not leak to the atmosphere. Conventional shaft

seals are lubricated by the fluid. A leakage flow is specified and

necessary for proper operation. Magnetic couplings replace

conventional shaft seals. KRAL three screw pumps with magnetic

coupling are hermetically sealed; the environment remains clean.

Can be used to 300 °C.

Thermal distortion and the temperature limits of elastomeric sealing

elements restrict the use of three screw pumps in high temperature

applications. If temperatures up to 300 °C are handled, KRAL three

screw pumps with magnetic coupling are the right choice.

Reduced life cycle costs.

Spare parts and maintenance costs of mechanical seals increase

lifecycle costs. The use of high quality mechanical seals in KRAL

three screw pumps is the standard. Even when properly applied,

mechanical seals are subject to wear. Spare parts and maintenance

costs arise. KRAL magnetic couplings are maintenance free, due to

the lack of a mechanical seal and increased life of the ball

bearing. The cost premium of a three screw pump with a magnetic

coupling will be typically amortized after only three years of

operation.

Protection of delivery medium.

With conventional seals, oxygen from the atmosphere may diffuse

through the sealing gap into the fluid. When the fluid crystallizes

from contact with oxygen, the process is interrupted and expensive

plant shut downs can result. KRAL three screw pumps with magnetic

coupling are hermetically sealed and protect the integrity of the

fluid.

Low price.

A magnetic coupling is required to transmit high torques. This can

make the magnetic coupling large and expensive. For high torque

transmission, strong magnets are necessary. The new generation of

KRAL three screw pumps are cost optimized and designed to the

requirements of the magnetic coupling. For many years, KRAL has

successfully manufactured magnetic coupled three screw pumps.

Experiences and actual field tested applications were incorporated

in the design.

Overload protection.

If the operating limits are exceeded, the three screw pump may

become damaged. Solids in the fluid can lead to blockade and damage

the spindle and the housing. In most cases the product produced is

not to specification, and the three screw pump must be replaced. If

the decoupling is controlled, and the three screw pump stops, the

three screw pump and magnetic coupling will suffer no damage. The

magnetic coupling can prevent consequential damage.

- Leak-free - no collection of residues.

- Extremely low maintenance.

- Hermetically

sealed - prevents contact with oxygen of the heavy fuel oil,

isocyanates,

and other reactive liquids. - Operating temperatures up to 300 °C.

- High flow and pressure capability.

*Please ask for other data.Technical data, Dimensions and Weights apply for the Series K. For higher pressures of up to 100 bar andflow rates up to 2,900 l/min, please provide application information for the Series L and C.