Products / Kral / Screw Pumps / Screw Pump Series W

KRAL Three Screw Pumps W Series.

The KRAL pump for special requirements.

The pump for special requirements.

KRALs W series pump is mainly used wherever a dirty or abrasive

media is required. The cartridge case is coated with a resilient

polymer. The plastic can absorb particles due.

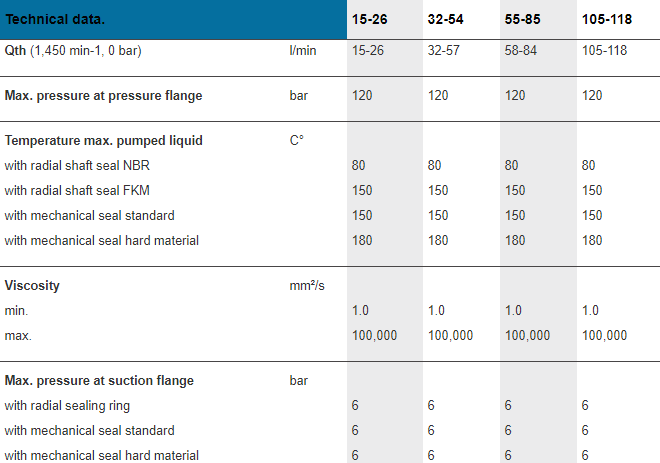

- Delivery rate: 15 to 290 l/min.

- Max. differential pressure: 120 bar.

- Viscosity: > 1 mm2/sec.

- Max. temperature: to 180 °C, magnetic coupling to 300 °C.

- Installation: Wet or dry.

- Spindle housing:

Nodular cast iron EN-GJS-400, polymer coated or other material

options. - Spindles: Steel, nitrided.

Operation, materials, components.

Water soluble machine tool coolant can be a very difficult pumping

service to handle. The fluids have a very low viscosity of only

about 1 mm²/s, must by delivered at high pressure and contain

abrasives, mostly metal residues.

It is due to the innovative design, and especially the casing

coating, that the advantages of the KRAL three screw pump can be

successfully applied to machine tool coolants. KRAL coats the

running casing with a resistant polymer. This synthetic material can

absorb particles. According to specifics of the application other

materials can also be used.

Water soluble machine tool coolants are pumped at high pressures of

up to 120 bar. Only at such high pressure is sufficient cooling and

flushing of the chips accomplished. The balancing cylinder of the

three screw pump has orifice insertions to reduce the leakage rate,

therefore efficiency remains high.

The screw material and the casing coating have been designed for

improved sliding properties in such a way that low viscosity fluids

is pumped with no problem. The KRAL machine tool coolant three screw

pump can be supplied for dry or wet installation. A mounting flange

has already been provided for vertical wet installation.

Special requirements.

Compared with other three screw pump principles, three screw pumps

have a number of oustanding qualities. The three screw pump delivers

continuously with alow pulsation rate and low noise level. They

achieve high flow rates even in small sizes. Cooling lubricants are

difficult liquids with viscosities as low as mm²/s. The fluid must

be delivered at high pressure, and contains abrasives, mostly metal

residues.

Thanks to the innovative design, particularly in regards to the case

materials, the KRAL three screw pump offers many advantages when

pumping water soluble coolant emulsions.

Contamination? No problem!

Metal residues in cooling lubricants can cause abrasive damage to

the three screw pumps internal surfaces. When precautions are not

taken, the case, the spindles and the ball bearing are affected.

KRAL coats the case with a resistant polymer, this synthetic

material can absorb particles within limits. Depending on the liquid

used, other materials can also be provided. Additionally, the three

screw pump is provided with a permanently lubricated outside bearing

which has no contact with the medium.

Installation options.

The KRAL cooling lubricant three screw pump can be designed for dry

or wet-well installation. For a vertical wet-well installation a

mounting plate is provided.

- Resistant, polymer-coated running casing absorbs particles.

- High pressure at low viscosity.

- Multiple installation variations available.

Your advantages: