Products / Kral / Screw Pumps / Screw Pump Series K

KRAL Three Screw Pumps K Series.

The economical, most sold KRAL pump.

Universal use up to 16 bar.

K series pumps are universal three screw pumps, making them the most

sold KRAL pump. The K pumps have a feed pressure of 16 bar and

housing made from nodular cast iron. They are approved for use

onboard ships. In addition, they are equipped with sealed external

bearings that are pre-lubricated for their lifetime so they are not

stressed by the material being pumped and require no maintenance.

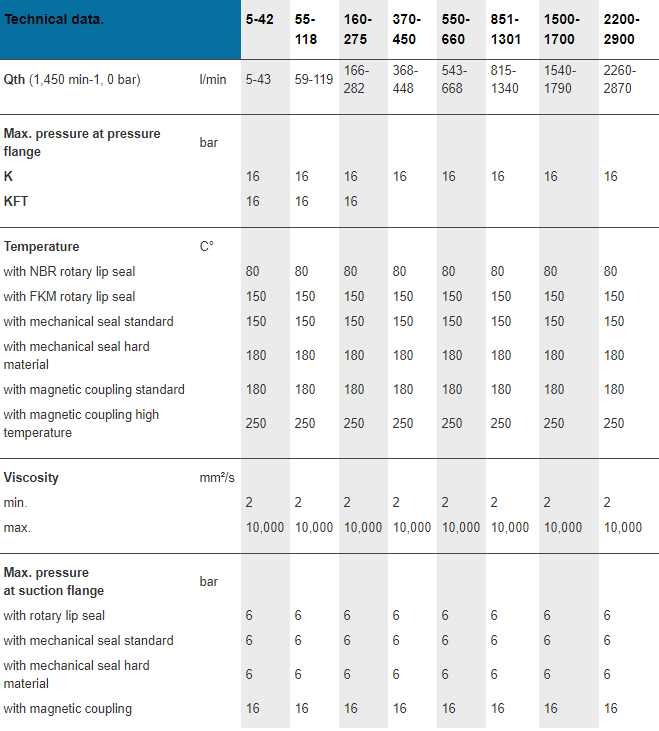

- Delivery rate: 5 to 2,900 l/min.

- Delivery rate KFT: 5 to 510 l/min.

- Max. differential pressure: 16 bar.

- Temperature range: -20 °C to 180 °C, magnetic coupling to 300 °C

- Housing: Nodular cast iron EN-GJS-400.

- Spindles: Steel, nitrided.

- Certifications: ABS, BV, CCS, DNV, GL, LRS, MRS, NK, RINA.

- ATEX: II 2 GD b/c group II, category 2.

- Heating: Electrical, fluid media and steam.

Operation, materials, components.

How the K three screw pump fits into the KRAL product program.

The K series three screw pump is available with DIN flanges in an inline

configuration, and the KFT series three screw pump is available with DIN

flanges at the top. Various installation methods are possible for

flange-mounting, pedestal and base three screw pumps.

Advantages of t hree screw pumps.

Compared to other types of pumps, KRAL three screw pumps offer high

capacity without taking up much space. This applies in particular at

high differential pressure. The three screw pumps are self-priming, with

low pulsation delivery and can be easily regulated. The single three

screw pumps, single stations and double stations are extremely compact.

All K three screw pumps have an internal safety valve.

Stop coupling damage.

With some liquids, residue can build up, which may cause the pump to

fail. A typical spot for residue to build up is at the mechanical seal.

The residue damages the ball bearing, which runs hot, melts the

elastomeric ring and damages the coupling. With the K series three screw

pump, there is a weep hole next to the mechanical seal, to prevent the

fluid from collecting and building up as residue.

The new generation three screw pumps series K has been thoroughly

reengineered. As the most sold universal three screw pump series K

offers a number of benefits. The three screw pump prevents the

accumulation of residue forming fluids by locating the leakage hole

before the ball bearing. Secondly, KRAL offers the advanced quality of

SiC mechanical seals, which contains graphite, as a solid lubricant to

reduce the coefficient of friction in dry running conditions. The O

rings with high fluorine content are suitable for higher temperatures

and are chemically stable. The three screw pump series K offers

innovative seal concepts. A proven selection of radial rotary shaft

seals, mechanical seals and a hermetically sealed magnetic coupling are

available as standard. A robust and compact design rounds off the

profile.

- No coupling damage through well placed leakage hole.

- Safety reserve in dry running.

- Low maintenance operation.

- DIN standard.

Your advantages: