Products / Parker / Thermal and Power Management / THERMFLOW T725 Non-Silicone, Phase-Change Thermal Interface Pads

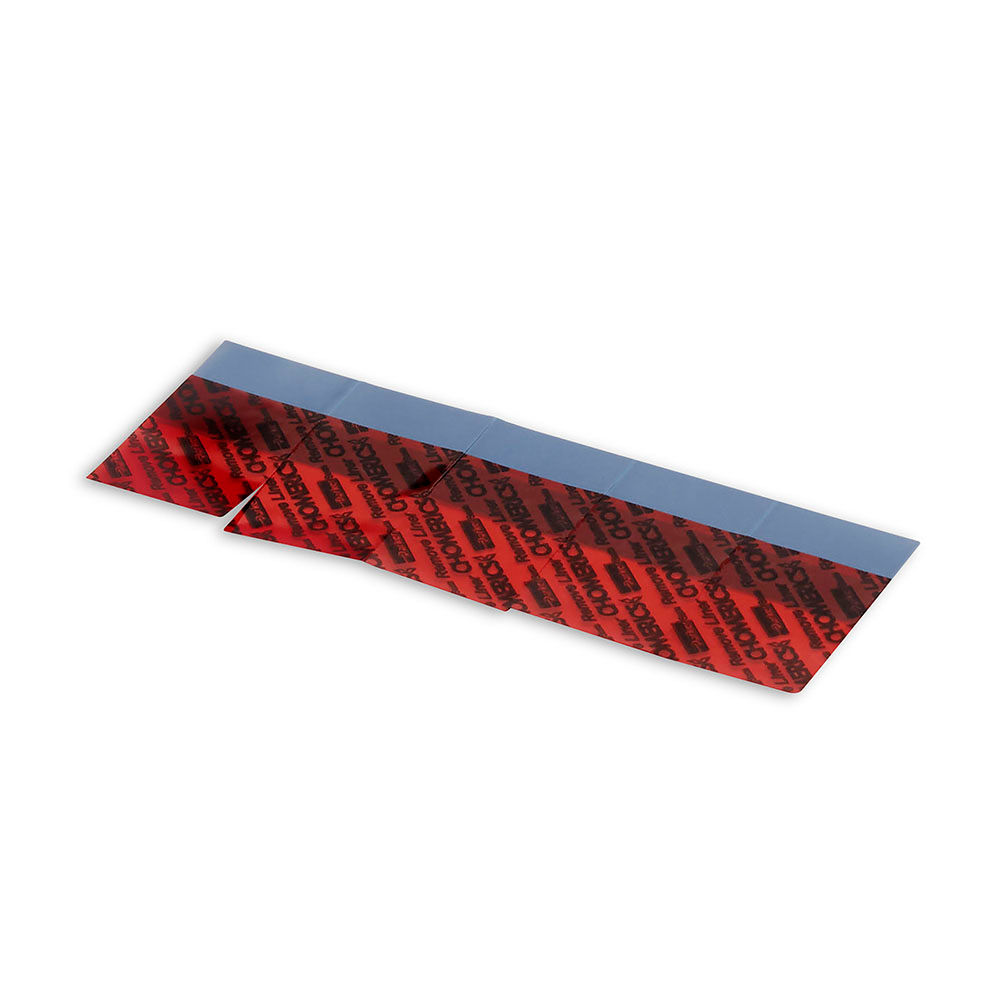

THERMFLOW T725 Non-Silicone, Phase-Change Thermal Interface Pads

THERMFLOW® T725 phase-change Thermal Interface Materials (TIMs) completely fill interfacial air gaps and voids with superior thermal performance and is ideal for vertical applications.

THERMFLOW® phase-change Thermal Interface

Materials (TIMs) completely fill interfacial air gaps and voids.

They also displace entrapped air between power dissipating

electronic components. Phase-change materials are designed to

maximize heatsink performance and improve component reliability.

Upon reaching the required melt temperature, the pad will fully

change phase and attain minimum bond-line thickness (MBLT) - less

than 0.001 inch or 0.0254mm, and maximum surface wetting. This

results in practically no thermal contact resistance due to a very

small thermal resitance path.

At room temperature, THERMFLOW materials are solid and easy to

handle. This allows them to be consistently and cleanly applied

as dry pads to a heat sink or component surface. THERMFLOW material

softens as it reaches component operating temperatures.

With light clamping pressure it will readily conform to both mating

surfaces.

This ability to completely fill air gaps and voids typical of

component packages and heat sinks allows THERMFLOW pads to achieve

performance superior to any other thermal interface materials.

Standard THERMFLOW products are electrically non-conductive however

metal-to-metal contact is possible

after the material undergoes phase-change, decreasing their

electrical isolation properties. PC07DM-7 is the only phase-change

materials recommended for use as a dielectric insulator.

Chomerics offers two types of phase change materials—traditional

thermal interface pads and Dual Phase Change Polymer Solder Hybrids.

Dual Phase Change Polymer Solder Hybrid Materials

Dual Phase Change Thermal

Interface Materials consist of binder and fillers which both phase-

change to exhibit the lowest thermal impedance of the phase-change

family. These Thermal Interface Materials provide superior long term

reliability and performance. For optimum performance, the pads must

be exposed to temperatures above 64ºC during operation or by a

burn-in cycle to achieve lowest thermal impedance and highest

thermal performance.

Features/Benefits

• Low thermal impedance

• Proven solution – years of production use in personal computer OEM

applications

• Demonstrated reliability through thermal cycling and accelerated

age testing

• Can be pre-applied to heat sinks

• Protective release liner prevents contamination of material prior

to final component assembly

• Tabs available for easy removal of release liner (T710, T725*,

T557, T777, PCO7DM)

* T725 is only offered with a tab

• Available in custom die-cut shapes, kiss-cut on rolls

• RoHS Compliant

Typical Applications

• Microprocessors

• Graphics Processors

• Chipsets

• Memory Modules

• Power Modules

• Power Semiconductors

Handling Information

These products are defined by Chomerics as “articles” according to

the following generally recognized regulatory definition for

articles:

An article is a manufactured item “formed to a specific shape or

design during manufacturing,” which has “end use functions”

dependent upon its size and shape during end use and which has

generally “no change of chemical composition during its end use.”

In addition:

• There is no known or anticipated exposure to hazardous

materials/substances during routine and anticipated use of the

product.

• The product’s shape, surface, and design is more relevant than its

chemical composition.

These materials are not deemed by Chomerics to require an MSDS. For

further questions, please contact Chomerics at 781-935-4850.

Application

Material may flow when oriented vertically, especially at higher

temperatures. This does not affect thermal performance, but should

be considered if appearance is important.

Clean Up

THERMFLOW material can be removed with solvens such a toluene, MEK

or isopropyl alcohol.

T725

• Excellent thermal performance

• Inherently tacky – no adhesive required

• Ideal for vertical applications

• Sticky n'ature limits flowing in vertical applications

• Tabs available for easy removal