Products / Parker / Emi Shielding / Connector Gaskets - EMI Gasketing With Pressure Seal

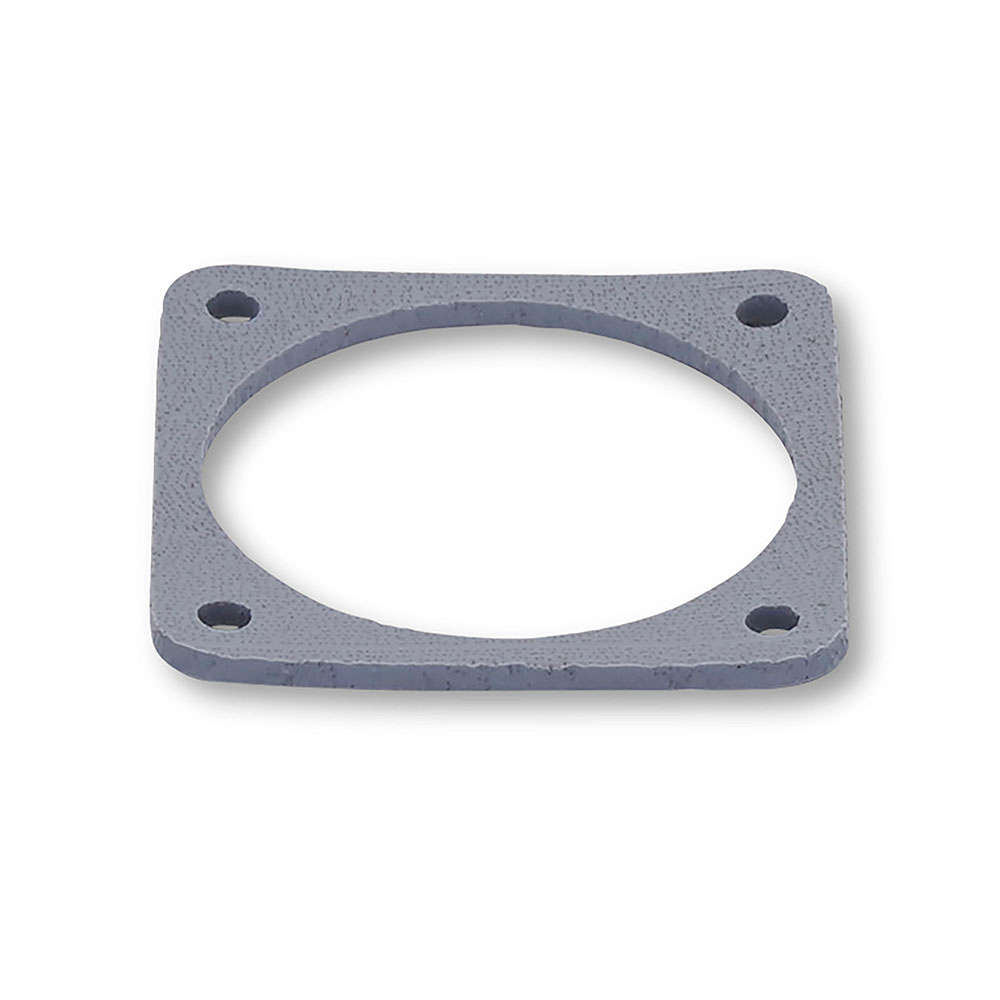

Connector Gaskets - EMI Gasketing With Pressure Seal

Parker Chomerics metal-based connector gaskets are die-cut from several sheet materials which suit various EMI shielding and pressure sealing requirements.

Parker Chomerics metal-based connector gaskets

are die-cut from several sheet materials which suit various EMI

shielding and pressure sealing requirements. They are available in

sizes for all standard AN Series Connectors, as well as for RF

types, JT, PT & PC, SO, SP and Bendix Connectors. Although these

materials provide effective EMI shielding performance upon initial

installation, they should be replaced if joints are opened and

reclosed.

EMI shielding is provided by oriented or expanded monel, or aluminum

wire. Pressure sealing is provided by silicone or neoprene

elastomer. POLASHEET gaskets are available with adhesive backing for

quick mounting on one of the mating surfaces.

Materials and Construction

Gaskets are cut from the materials listed below, in sizes ranging

from 0.688 in. (17.48 mm) to 3.25 in. (82.55 mm) square to fit

connector shell sizes 6 to 48. Fastener holes are provided at each

corner for mounting (slots in silicone- filled METALASTIC gaskets).

The materials are described in detail on the previous pages.

POLASHEET Gaskets: Perpendicular monel wire in solid silicone, 0.062

in. (1.57 mm) thick. Compensates for 0.008 in. (0.20 mm) joint

unevenness. Excellent EMI shielding and pressure sealing. Available

with pressure- sensitive adhesive backing.

METALASTIC Gaskets: Silicone or neoprene-filled aluminum mesh, 0.020

in. (0.51 mm) thick. Recommended where space is tight. Compensates

for no more than 0.002 in. (0.05 mm) joint unevenness. Note: Use

silicone for temperatures to 500°F (260°C).

PORCUPINE METALASTIC Gaskets: Severely expanded monel,

silicone-filled, 0.030 in. (0.76 mm) thick. Compensates for only

0.005 in. (0.127 mm) joint unevenness. Best for breaking through

non- conductive surface films.